TOPIC #12

Li-ion cell solutions for sustainable and cost-competitive batteries

Research area: Battery Manufacturing & Recycling

Keywords: New Materials & Electrolytes

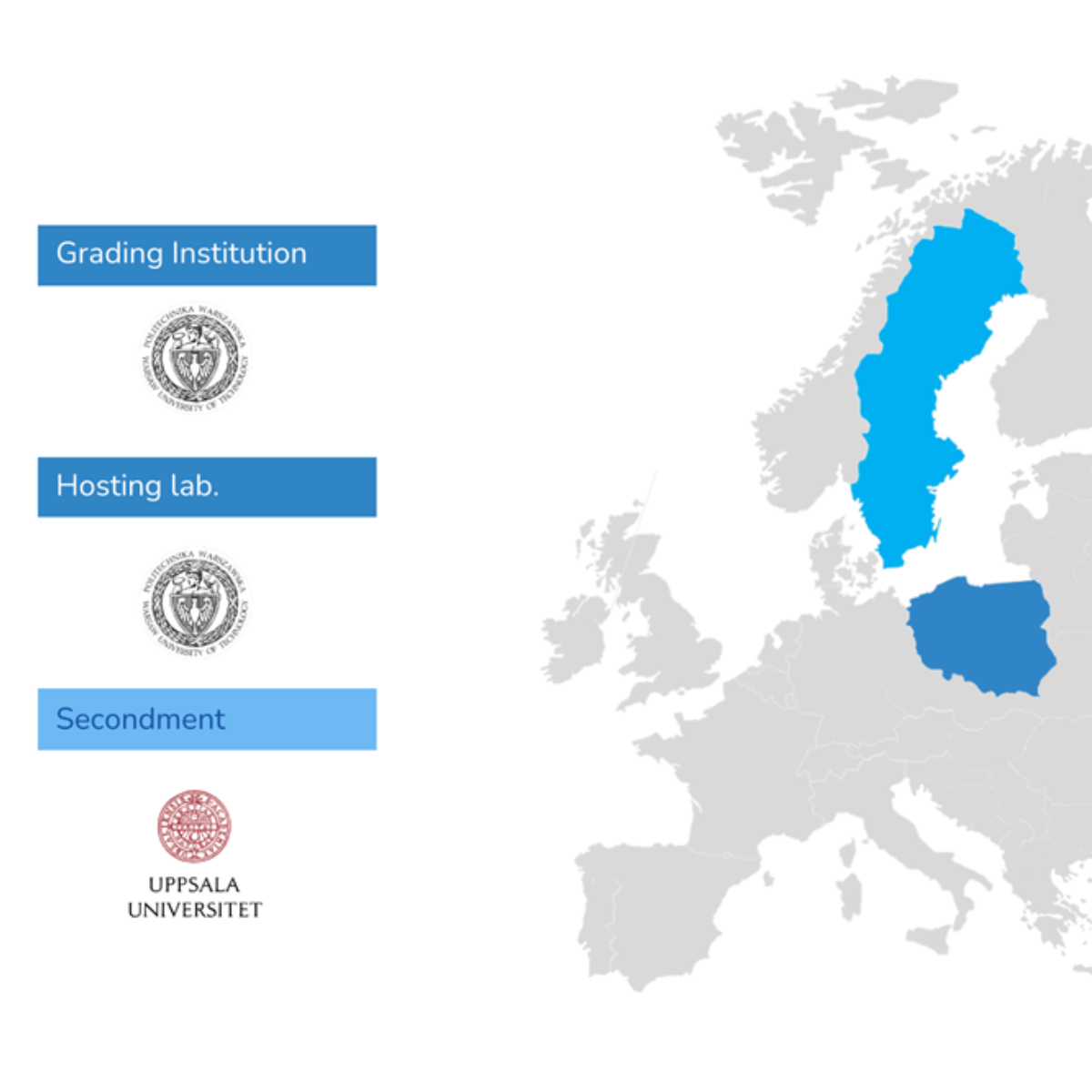

Supervising team: Leszek NIEDZICKI (WUT) & Daniel BRANDELL (Uppsala University)

Abstract

Join the work for more sustainable, resources-efficient and cost-competitive Li-ion batteries!

Electrification of all kinds of transport accelerates. Mass energy storages enable renewable energy expansion. Further growth of the battery industry is urgently needed. For that it requires sustainable battery chemistry, easier for recycling. Also, cost-efficient, easy handled manufacturing is needed. Meanwhile, keeping environmental safety is crucial, as use of abundant raw materials for strategic resources independence. But with current state-of-the-art it is not possible to achieve all those goals at the same time. New chemistry is needed. And what better to improve than electrolyte – the most unstable component of Li-ion batteries.

Development and optimization of electrolyte compositions containing new proprietary salts (including first working non-fluorine salt) will be the first step. Then the compatibility between these new electrolytes and electrodes made with sustainable materials and through cost-efficient processes will be investigated. Finally, prototypes will be built using repeatable and easy to upscale methods.

Project will require: samples preparation and cells assembly in glovebox; performing and analysing basic electrochemical measurements, analysis of thermal, spectroscopic and physicochemical techniques results as necessary; performing cells/batteries testing, assembly and cycling; travel for at least two few-month periods to Sweden for battery tests.

Interest for the student

Expected mobility: Secondment at Uppsala University, Department of Chemistry - Ångström Laboratory is expected to take ca. 1-2 months at around the middle of the PhD project as well as another ca. 2-3 months at the close to the end of the PhD project, as ESR will use Ångström Laboratory facilities to analyse at least two iterations of half-cells/full-cells at various conditions and their State of Health with diagnosis on individual parameters and properties of cell components degradation during cycling. Participation in both Student/PhD-focused conferences as well as international battery-field conferences is expected from the ESR particularly towards the end of the project in order to disseminate results. Finally, ESR will be encouraged to participate in numerous workshops, trainings and summer/winter schools offer from both WUT (on-site and outgoing) and other partner institutions.

Career opportunities: Given that this PhD project will involve use and learning both wide range of electrochemical, spectroscopy, thermal, physicochemical and basic synthesis methods, as well as cell components formulation, the career prospect for the ESR finalizing this particular PhD project would be work for R&D center of any major batteries or cell components manufacturer, as well as raw materials/intermediates manufacturers for the battery industry or battery pack developers. The knowledge from the inside out of the whole cell design, prototyping and all investigative methods for characterization of cell and its components as well as learning the holistic approach towards sustainable design of the battery cells would predestine the ESR for future R&D manager or senior researcher/project manager at R&D divisions. Also, due to the theoretical background provided to the ESR, academia career at applied research faculties/departments of universities or institutes specializing in battery or energy storage research is also a viable alternative.

Contacts

IMPORTANT: you may contact the potential supervisors to have more information about the topic, however, sending them your application directly is not permitted.